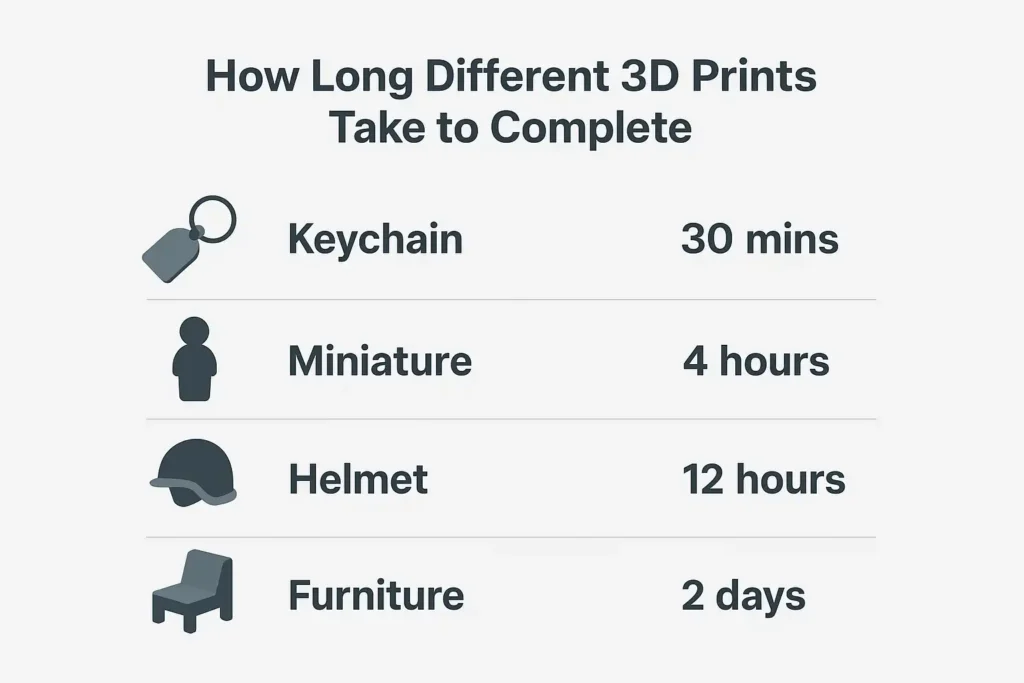

A 3D print can take 30 minutes to several days. This depends on the print size, printer type, and settings. For example, a simple keychain takes about 30 to 60 minutes. In contrast, a full-size helmet might take 12 hours or more to print.

The time it takes to 3D print varies widely because the 3D printing process involves building an object layer by layer. The more complex the model and the finer the layer height, the longer it will take to print.

So, if you’ve ever wondered “how long does it take to 3D print something?”, the short answer is — it depends on what you’re printing and how your 3D printer settings are configured.

Why Print Time Matters in 3D Printing

Print time is more than just waiting; it impacts the cost, quality, and usability of your final product.

- Faster prints often mean lower detail and rougher surfaces.

- Slower printing creates smoother results but can take longer to print and may delay projects.

- Businesses and hobbyists must find a balance between speed and quality of the print.

For instance, if you run a 3D printing service, knowing how print speed impacts quality helps you give realistic delivery times and manage expectations. Hobbyists can change their printer settings to print faster while keeping detail.

Knowing 3D printing speeds lets you plan better, save time, and boost print success.

What Determines 3D Print Time

The time it takes to 3D print a part depends mainly on the size of the 3D model, the layer height, and the printer settings you choose. Other things — like infill, supports, the type of printer, and filament — also affect print time and final quality.

I’ve tested common settings across FDM and resin printers and compared results. Here are the main factors that impact print time and how they each affect the duration of 3D printing.

Model Size and Geometry

- Why it matters: Taller prints need more layers. More layers take more time.

- A 50 mm toy and a 100 mm toy with the same layer height need different layer counts. The taller toy requires roughly twice as many layers, so it will take about twice as long to print.

- Geometry effects: Thin walls, many small details, or many separate parts on the bed increase travel and print time. Complex shapes can slow the print head and increase the overall print time.

Layer Height (Resolution) – Quality Versus Speed

- What it is: Layer height is how thick each printed layer is (for example, 0.1 mm or 0.2 mm).

- Trade-off: Smaller layer height = better surface finish and detail, but more layers and longer print time. Larger layer height = faster print, but lower quality.

- Rule of thumb: Doubling layer height roughly halves the print time, but it reduces detail.

- Practical pick: Use 0.2 mm for fast prototypes and 0.1 mm for display-quality prints.

Nozzle Diameter and Extrusion Width

- Nozzle role: A larger nozzle lays down thicker lines, so each layer takes fewer passes. That usually cuts the time to print.

- Example: A 0.8 mm nozzle prints a large prototype faster than a 0.4 mm nozzle, but it will show rougher surface details.

- Limits: The printer’s hotend and filament feed need to manage the higher flow rate. If they can’t, print quality will suffer.

Print Speed, Acceleration, and Motion Settings

- Print speed controls how fast the print head moves while laying filament. Acceleration and jerk settings control how quickly the head changes speed.

- Higher print speed cuts down time, but it can cause ringing, missed steps, or weak bonding. Acceleration tuning is needed to keep the quality acceptable at higher speeds.

- Practical note: Increase speed a little and test; don’t jump to max speed without tuning the printer.

Infill Percentage, Pattern, and Wall Count

- Infill is the internal structure of your 3D printed parts. Higher infill means more material and more printing time.

- Example: 80% infill prints much longer than 15% infill.

- Patterns: Gyroid or cubic infill patterns print at different speeds. Some patterns print faster while maintaining good strength.

- Walls: More wall count (perimeters) improves strength but increases print time.

Supports, Orientation, and Cooling Effects

- Supports: Adding supports increases print time and post-processing time. Support density and support type affect how much extra time printing takes.

- Orientation: Rotating the model can reduce height or reduce the need for supports, which reduces the time it takes to print something.

- Cooling: Cooling settings and layer-to-layer cooling time can slow prints. Some materials and fine features need extra cooling time between layers.

Printer Technology: FDM Versus SLA/DLP (and Other Methods)

- FDM (filament) printers: Time depends on layer height, nozzle, and infill. FDM often takes longer for fine detail.

- SLA/DLP (resin) printers: Time depends on exposure time per layer and the number of layers. For small, detailed parts, resin can be faster and give better detail.

- SLS and industrial methods can print multiple parts at once. However, they require long post-processing steps.

- Note: Manufacturer specs and community tests show that resin printers often produce highly detailed miniatures faster than FDM at the same perceived quality level.

Real-World Time Examples for Different Print Types

Actual print times vary, but common objects follow easy ranges: tiny items often finish in less than an hour, medium objects take a few hours, and large or high-detail objects can take many hours or even take several days. These examples use typical print settings to show realistic hours to print for each object type.

Expanded examples, settings, and table: Below are practical examples and the settings used, so you can compare how different print settings and printer types affect total print time.

Tiny Prints (Keychains, Flat Tokens)

- Typical print time: 30 minutes to 1 hour.

- Settings example: FDM with 0.2 mm layer height, 0.4 mm nozzle, 10–20% infill.

- Notes: Tiny flat tokens print quickly because they have few layers. If you increase detail or use a smaller layer height, they will take longer.

Small Functional Parts (Phone Stands, Hinges)

- Typical print time: 1–4 hours.

- Settings example: 0.2 mm layer height, 20–40% infill, 2–3 wall counts.

- Notes: Adding stronger infill or more walls raises print time, but it improves durability.

Medium Models (Miniatures, Figurines)

- Typical print time: 4–12 hours (FDM); 2–6 hours (resin for similar-sized miniatures).

- Settings example (FDM): 0.12–0.2 mm layer height, fine detail, 10–20% infill.

- A resin printer offers high detail in a similar or shorter print time. Print time is the result of layer exposure times times the number of layers. Also, adding detail doesn’t always increase the time needed.

Large Prints (Helmets, Furniture, Full-Size Props)

- Typical print time: 12–48+ hours; large pieces may take several days if printed at high quality.

- Settings example: 0.2–0.3 mm layer height for a faster build, higher infill for structural parts.

- Strategy: Split large models into parts to fit the bed and to shorten individual print jobs.

Resin Prints (Layer Exposure-Based Printing)

- Typical print time: 2–12 hours for small to medium parts.

- Key factor: Time = number of layers × exposure time per layer. Resin detail printing usually adds little extra time compared to lower detail. So, it can be efficient for making finely detailed parts.

- Post-process: Add washing and UV curing time to the total project time.

Metal & Industrial Prints (Complete Lead-Time Breakdown)

- Typical lead time: days to weeks in total, depending on post-processing.

- Why long: Metal printing often includes printing, heat treatment, machining, and inspection. The actual printer time can take hours to days. But post-processing adds more time from design to the finished part.

- Use case: Choose metal printing for strong, functional parts when lead time and cost are acceptable.

Quick comparison table (typical)

| Object / Tech | Typical Time Range | Typical Settings |

|---|---|---|

| Keychain (FDM) | 0.5–1 hr | 0.2 mm layer, 10% infill |

| Phone stand (FDM) | 2–4 hrs | 0.2 mm, 20–30% infill |

| Miniature (FDM) | 4–12 hrs | 0.12 mm, 10% infill |

| Miniature (Resin) | 2–6 hrs | 50–100 µm layers |

| Helmet / Large FDM | 12–48+ hrs | 0.2–0.3 mm, split parts |

| Metal part (industrial) | Days–Weeks | Powder bed or binder jet + post-process |

How to Estimate Print Time Accurately

The easiest way to estimate 3D printing time is to check your slicer’s print time. But keep in mind, it’s rarely 100% accurate. The actual printing time depends on your printer’s real speed, filament type, and cooling or retraction settings.

If you want a more realistic time to print, use slicer tools, plugins, and a few quick manual checks. Here’s how you can get closer to the real number.

Why Slicer Time Estimates Can Be Inaccurate

Most slicer programs like Cura or PrusaSlicer try to predict print time based on movement paths and print speed, but they don’t always match real-world performance.

Reasons they can be off include:

- Acceleration and jerk settings: Your 3D printer doesn’t often run at full speed. It speeds up and slows down when turning corners.

- Filament flow changes: Some filaments (like PETG or TPU) require slower printing.

- Cooling delays: If layers are small, the printer pauses for cooling, which adds time.

- Retraction and travel moves: These are often underestimated by slicers.

Tip: Your slicer’s estimate may say 5 hours. However, actual printing can take 6 to 7 hours, depending on the conditions.

Tools and Plugins for Improved Time Predictions

Modern slicers and firmware now include advanced ways to calculate 3D printing time more accurately.

Useful tools include:

- Cura’s “Post Processing Plugin” lets you add real acceleration and jerk values. This improves timing.

- OctoPrint + PrintTimeGenius Plugin: Uses G-code analysis and machine learning to improve predictions.

- PrusaSlicer’s “Physical Printer Profile”: Lets you define real print head acceleration to match your printer.

These tools help close the gap between slicer estimates and actual print times. This is especially useful when testing new 3D printer settings.

A Quick Manual Calculation Method You Can Use

If you want a simple way to estimate 3D printing time yourself:

- Find the total filament used (in meters) from your slicer.

- Find your print speed (in mm/s) and layer height.

- Use this rough formula: Estimated Time (hrs)=Average Speed (mm/s)×3600Total Filament Length (m)×1000

- Add 15–30% extra for acceleration, cooling, and retraction delays.

This provides a good estimate of print time. It helps you plan better and avoid surprises

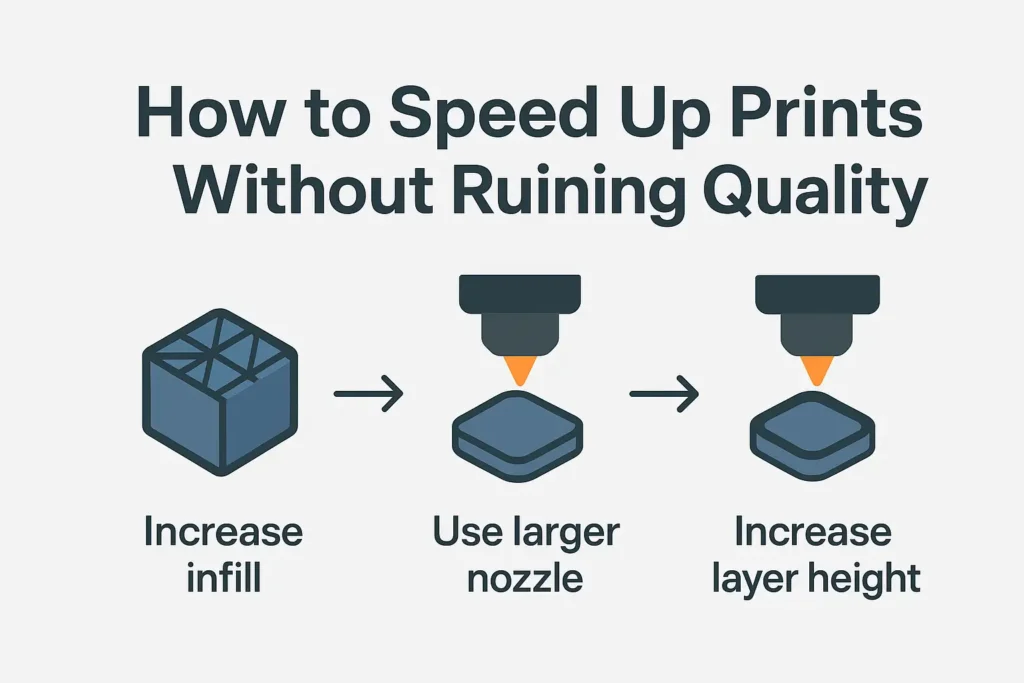

How to Speed Up Prints Without Ruining Quality

You can speed up your 3D prints by changing the layer height, nozzle size, infill, and motion settings. But remember, each change can affect print quality. The key is balance: make your 3D printer work smarter, not harder.

Here are some tested ways to speed up your 3D printing while keeping detail and strength.

Choosing the Right Layer Height and Nozzle Size

- Layer height: Use 0.2 mm for most parts; go lower (0.1 mm) for high detail or higher (0.3 mm) for faster builds.

- Nozzle size: Larger nozzles (0.6 mm or 0.8 mm) reduce layer count and increase print speed.

- Combination tip: A 0.6 mm nozzle with a 0.25 mm layer height can cut print time by 30–40% while keeping acceptable detail.

A part that takes 12 hours to print at 0.1 mm may finish in 7–8 hours at 0.25 mm with a wider nozzle.

Increasing Extrusion Width Safely

Wider extrusion means each filament line covers more area. This leads to fewer passes and faster printing. Keep extrusion width up to 120–150% of your nozzle diameter to maintain proper bonding.

- Example: 0.4 mm nozzle → 0.48 to 0.6 mm extrusion width is safe. This can reduce print time without lowering the strength too much.

Using Adaptive Layer Heights and Draft Modes

Many slicers have adaptive layer height. They use thicker layers for flat or simple areas and thinner layers for detailed parts.

- Saves printing time based on geometry complexity.

- Cura’s “Draft Mode” and Prusa’s “Variable Layer Height” are excellent tools. This gives you fine detail where needed and fast printing where not.

Optimising Infill Pattern and Reducing Supports

- Use low infill: 15–25% is enough for most functional parts.

- Choose fast infill patterns like Lines or Lightning instead of Gyroid or Grid.

- Reduce supports: Re-orient your model to print with fewer overhangs. Less infill and fewer supports can decrease overall print time by half in many cases.

Tuning Firmware: Acceleration, Pressure Advance, and Motion

Tuning your firmware settings can make a big difference:

- Acceleration: Increase slightly (e.g., 1000 → 2000 mm/s²).

- Pressure Advance / Linear Advance: Keeps flow stable during quick starts and stops.

- Jerk / Junction Deviation: Smooths motion and reduces vibration at higher speeds.

Proper tuning means your printer can print faster without affecting print quality.

Batch Printing and Build-Plate Nesting Techniques

Instead of printing one object at a time, try batch printing multiple parts together. This makes better use of the print bed and saves time. The printer needs fewer warm-ups and cooldowns. Use build-plate nesting to arrange objects efficiently. But leave space to prevent heat buildup or nozzle collisions.

Common Causes of Unexpected Delays and How to Avoid Them

Even top 3D printers can take longer than planned. This can happen because of failed prints, poor adhesion, filament jams, or hardware problems. Knowing what slows you down helps you avoid wasted hours to print and filament.

Failed Prints: Adhesion, Warping, Filament Jams

- Bed adhesion issues: Prints lift or detach midway, forcing restarts.

- Warping: Common with ABS; it slows projects and wastes time.

- Filament jams: Stop extrusion and ruin prints. Prevention: Use a glue stick or PEI sheet for adhesion, dry filament, and keep a clean print head.

Filament or Temperature Issues That Slow You Down

Every filament has an ideal temperature.

- Too cold (→ poor bonding and possibly slower printing).

- Too hot → stringing and oozing that increase retractions and delays. Always check the recommended range for your filament. Run a temperature tower test before key prints.

Power Loss, Hardware Reliability, and Print Recovery

Power cuts or SD card errors can ruin long prints that take several hours. Use:

- UPS (Uninterruptible Power Supply) to handle short outages.

- Power-loss recovery feature (in Marlin or Klipper firmware) to resume after a failure.

- Keep cables tight and avoid loose connections to maintain hardware reliability.

Slicer Errors and Bad G-Code Settings

Sometimes bad slicer settings cause long retractions, unnecessary moves, or overheating, which affect the time it takes to complete a print.

- Double-check print settings before slicing.

- Preview the G-code path to see if the slicer added unwanted travel moves. A small check before printing can save hours of print time later.

Safety, Monitoring, and Overnight Printing Realities

Running a 3D printer overnight can be safe if you take the right steps. However, it’s never entirely without risk. You must balance time-saving with safety.

Is It Safe to Leave a 3D Printer Running Overnight?

Technically, yes, but you must monitor it.

- Risks: Overheating, power surges, or nozzle clogs.

- Safety: Use a smoke detector, a fireproof mat, and keep your printer in a ventilated area. Resin printers emit fumes — keep them in enclosed, ventilated spaces only.

A Practical Safety Checklist for Overnight Printing

Before printing overnight:

- Tighten all wiring and connectors.

- Ensure the print bed and nozzle are clean.

- Use reliable firmware and thermal runaway protection.

- Keep flammable materials away.

- Use time-based cameras or smart plugs for remote cut-off.

This simple list keeps your 3D printing process safe and reliable.

Remote Monitoring Tools and Methods

To monitor long prints safely:

- OctoPrint / Klipper + webcam: Watch your print from your phone.

- TP-Link smart plugs let you turn off your printer remotely.

- AI-based monitoring (Obico): Detects failed prints automatically.

With these, you can print overnight, speed up your 3D printing, and still stay safe.

Total Project Time: Don’t Forget Post-Processing

When people ask, “How long does 3D printing take?” they often only think about the printing process itself. But the total project time doesn’t stop when your 3D printer finishes the job. After printing an object, you still need to do some post-processing. This includes sanding, curing, painting, and assembling. Sometimes, this can take longer than the actual print. Post-processing time depends on the print size, materials, and 3D printing technology. It can be a quick polish or take all day. Ignoring this step can give you a false idea of how long it takes to 3D print something from start to finish.

Sanding, Smoothing, Curing, and Finishing Time

Once the 3D print is done, most models need finishing touches to look polished or work well. Here’s how each step can add time:

- Sanding and Smoothing: Getting rid of layer lines or rough spots can take 15 minutes to a few hours. It all depends on how smooth you want your model. Larger models or those with detailed textures naturally take longer.

- Curing (for resin prints): If you use resin-based 3D printing technology, you’ll need to cure the part under UV light. This step usually takes 30 minutes to 2 hours, but is crucial for strength and durability.

- Painting and Coating: Applying primer and paint can slow down the print project by several more hours, especially if you wait between coats.

- Assembly: If your print is made up of multiple parts, gluing or bolting them together can add extra time.

The printing process takes about 4 hours for small parts and up to 12 hours for medium ones. Post-processing can then double that time. Always factor these steps in when estimating how long it takes to print an object from start to finish.

When Post-Processing Takes Longer Than the Print

In many cases, post-processing takes longer than the actual 3D print — especially for high-quality or decorative parts. This happens because:

- Complex models with intricate details require slow and careful sanding.

- Resin prints often need washing, curing, and polishing, which extends project time.

- Large prints may need trimming or gap-filling before painting.

For example:

- A simple keychain might take anywhere from 30 minutes to print and 10 minutes to sand and polish.

- But a full-size helmet could take 12 hours to print and another 8 hours to finish properly.

This shows that while 3D printing speeds have improved, the time it takes to 3D print something doesn’t always include the finishing process — and that’s where most people underestimate their total project duration.

When to Outsource or Upgrade Rather Than Optimise Settings

Sometimes, no matter how you change your printer settings, speed, or infill, your 3D printer can’t go faster without losing quality. In these cases, you could save time and effort by outsourcing the print job or getting a new printer.

Understanding how long it takes to 3D print depends on your machine’s limitations. If your prints take days or 3D printing is too slow for your deadlines, it’s time to look at your options.

Criteria for Outsourcing 3D Prints

Outsourcing your print can make sense when:

- You have bulk orders or need multiple models printed simultaneously.

- You need professional-grade quality, such as metal or resin parts that your home printer can’t handle.

- The print takes too long on your personal printer (for example, something that could take anywhere from 2 to 5 days).

- You need specific materials or finishes that require industrial-grade machines.

Professional services use advanced types of 3D printing technology like SLS, SLA, or DMLS, which can print faster and with higher precision than typical desktop printers. Outsourcing also means you can focus on design and testing while experts handle the printing process and post-production work.

When Upgrading Your Printer Is the Right Move

Upgrading your 3D printer can save money if you print often. Here’s when it makes sense:

- Your current printer needs frequent maintenance or breaks down often, which can slow down the printing.

- You want to print larger objects, and your current printer’s build volume is too small.

- You want faster 3D printing speeds without losing detail or quality.

- You use old technology. Newer printers have smarter motion systems, improved cooling, and faster firmware. These features greatly cut down printing time.

For example, switching from an older FDM model to a newer CoreXY or resin printer can cut overall print time by 30–50%. In simple terms, if your prints now take 10 to 12 hours, a new setup could do them in 4 to 6 hours. Plus, you’d get better results.

If your 3D printer is slow, upgrading could save you time and frustration later. This is especially true when both quality and speed count.

Quick Reference Cheat Sheet for 3D Print Times

If you’ve ever wondered “how long does 3D printing take?”, this quick guide gives you straightforward answers. While the time it takes to print an object depends on many factors — like the size of the print, design complexity, and type of 3D printing technology — these quick references will help you estimate without diving too deep into technical details. Whether you’re a beginner trying to speed up your print or a hobbyist planning a weekend project, this cheat sheet gives you realistic time frames for common 3D prints.

One-Line Answers for Common Questions

Here’s a quick list of answers to common questions about 3D printing speeds and project times:

- How long does 3D printing take for a small item?

- A small item like a keychain can take anywhere from 30 minutes to 2 hours, depending on the complexity and print quality settings.

- How long does it take to 3D print medium models?

- A medium model, such as a phone stand or small figurine, usually takes about 4 hours to print. However, if you choose a higher resolution, it can take 6 to 8 hours.

- How long does it take to print a large object?

- Large models, such as helmets or props, can take anywhere from 12 to 48 hours, based on the speed of 3D printing and the size of the print.

- Does the type of 3D printing technology affect time?

- Yes. FDM printers are often slower but cheaper. In contrast, resin-based and other 3D printing technologies can be quicker, but they might need more post-processing.

- Can print settings slow down the print?

- Absolutely. A smaller layer height, high infill, or intricate details can easily slow down the print, even if the machine is fast.

- How to speed up your print without losing quality?

- Use draft mode, adjust layer height, or increase nozzle size slightly. But remember — faster prints can sometimes reduce the quality of the print if settings aren’t balanced.

A Simple Time-Saving Checklist

Here’s a handy checklist to speed up your print and make sure you are not wasting time unnecessarily:

Choose the right 3D printing technology: Select a printer suited to your model. Resin printers produce smooth results but can take longer due to curing. FDM printers are faster for rough prototypes.

Adjust layer height and infill: Larger layers and lower infill percentages significantly reduce the time it takes to print.

Simplify your model: If you can, remove fine details or overhangs that require supports. This can cut hours off your total print time.

Avoid slower printing speeds: Make sure your firmware, slicer, and print speed settings are optimized. Unnecessary retractions or slow-motion settings can slow down the print dramatically.

Plan for post-processing: Always remember that finishing — like sanding or painting — might take anywhere from 30 minutes to several hours, depending on your material and model type.

Monitor and maintain your printer: Regular cleaning and calibration prevent print failures that waste both time and filament.

Experiment with print settings: Each printer behaves differently. Test shorter prints first to find the right balance between the speed of 3D printing and the quality of the print for your specific design.

This cheat sheet isn’t just about the time it takes to 3D print. It’s also about knowing what affects those times and how to manage them. By applying these quick insights, you can speed up your print, plan better, and avoid surprises — no matter what type of 3D printing technology you use.

Conclusion: How Long Does It Really Take to 3D Print Something?

So, how long does 3D printing take? The short answer is — it depends. A simple object can take anywhere from 1 hour to print, while a complex model might take approximately 24 hours or even more. The time to print largely varies based on your printer settings, material type, and design complexity — but many other factors also play a role, such as post-processing, layer height, and cooling.

When you print compared to others using different 3D printers, you’ll quickly see how 3D printing technology and hardware quality can make a big difference. For example, a beginner desktop printer might take twice the time to print than one designed for industrial use. Larger models or detailed projects take longer to print. This is especially true if you use slow print speeds or finer layer resolutions for a smoother finish.

In short, there’s no fixed number for how long it takes to typically print something — a print might take just a few hours for small items or stretch across days for bigger, detailed models. Painting or finishing a 3D print can add more time to your project, even after printing.

However, by understanding what factors affect the print and learning how to optimize them, you can reduce waiting times and still maintain great quality. The best approach is to plan ahead, experiment with different 3D settings, and improve with every project. Whether you print overnight, print throughout the week, or outsource to professionals, knowing how each stage impacts time helps you achieve consistent, efficient, and beautiful 3D printed results — every single time.

Frequently Asked Questions

Q1. How long does it take to 3D print a 2000 sq ft house?

A 2000 sq ft 3D-printed house can take anywhere from 100 to 200 hours, depending on the printer size, concrete curing time, wall thickness, and printing speed. Some large-scale printers can finish it in as little as one week with continuous operation.

Q2. How many walls should my 3D print have?

Most 3D prints perform well with 2–3 perimeter walls. However, if you need extra strength or durability—like for mechanical parts or load-bearing prints—use 4 walls for better rigidity and impact resistance.

Q3. Is it safe to run a 3D printer in a house?

It’s safe if proper ventilation and fire precautions are in place. Always print in a well-ventilated room, use non-toxic filaments (like PLA), and never leave the printer completely unattended for long periods.

Q4. How many 3D printers can you run off one outlet?

Generally, you can safely run one 3D printer per household outlet. Running multiple printers from the same outlet can overload the circuit and pose a fire hazard. Always check the printer’s power rating (in watts) before connecting more than one.